After working through the maquette, I started by sourcing styrofoam to see what kind of cost would be required to create this piece. While I would have rather had a solid styrofoam block, at the time I started this, I was unable to source anything close to me. Shipping would have taken too much time and was prohibitively expensive. So I made the decision to simply glue up my own block from readily available styrofoam sheet. Halfway through this process, I was able to contact two companies in my area so that, should I decide to continue with large sculptures, I won’t have to go through the gluing up process.

Gluing up the 4x4x4 foot block

The block was made form twelve 4ftx8ftx2inch styrofoam insulation panels. It took a couple of sessions to get it all finished. The first photo shows the block in process at 26 inches in height – a little over halfway done. The second photo gives some idea of the size with the unglued panels leaning against a Honda Fit.

Styrofoam Block Complete!

The finished 4 sq ft styrofoam block. It’s probably a good thing I couldn’t afford an 8 sq ft block as I could barely reach to the center to apply the adhesive.

This requires a twenty-four hour cure time to make sure the adhesive has bonded with the styrofoam. Once everything is set, the rough carving with the hot knife can begin.

After I started working on the final diagram for the sculpt, I realized that a perfectly square block was not going to yield the sculpt I wanted without a lot of waste. So I removed the last four sheets, as a single unit, before the glue had time to set. This chunk will get glued on to the back in order to extend the hair.

Flattening the block allowed for resolution of some design issues with the hair as well. It will be a slightly smaller sculpture, overall, but I like this design much better.

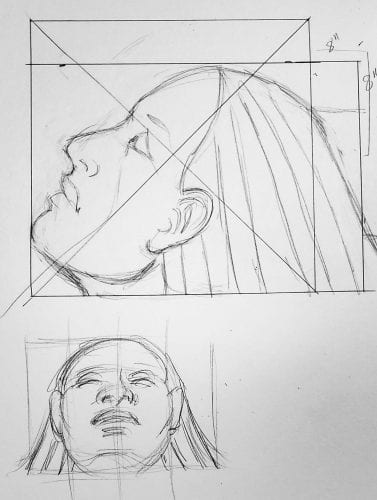

Transferring the Sketch onto the Block

Transferring the Sketch onto the Block

Major lines were marked on the block both for the side and for the face. Everything was marked into quarters and in angled eighths on the side.

Because I wanted to save as much of the upper left corner as possible, I built a wood sled for my hot knife. This gave me both a straight edge to cut along and allowed me to stair step down in order to save a good chunk of material.

This particular model of hot knife allows for the use of wire that can be bent in any shape. So I played with that while roughing the form out of the block.

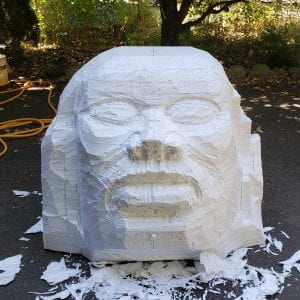

Chunking Out The Profiles And Big Shapes

I could have really used a wide hot wire for this part. The lines formed by the glued up sheets actually helped as landmarks so while it looks messy and took a bit of time, it wasn’t too bad.

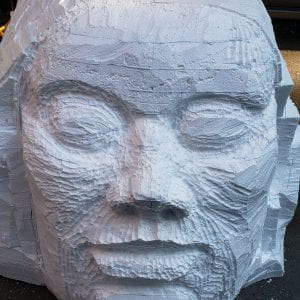

Working on the Rough Out Stage of the Face